Zhongfan Liu, founding president of Beijing Graphene Institute, describes how the institute is pioneering the industrialization of new graphene materials

What is the role of the Beijing Graphene Institute (BGI) and why was it created?

Officially opened in 2018, the BGI is committed to building a world-leading graphene R&D cluster and developing the worldwide graphene industry. Graphene is an emerging strategic material and while the roadmap to industrialization is long and full of challenges, the BGI is aiming to accelerate it through a collaboration between government, industry and academia. We believe we are on the eve of a “graphene era”.

Who funds the institute?

The BGI is jointly funded by the Beijing municipal government and social capital funds with 320m RMB ($50m) as registered capital and about 200m RMB invested each year. The institute comprises two legal entities – a research centre that receives funding from local governments and a company focusing on business development.

We believe the best is yet to come. Graphene has a big potential in many applications

How many people work at the institute and is that set to grow in the future?

We currently have around 250 staff, which is growing at a rate of about 100 new staff every year. Despite its short history, BGI has been successful in attracting people and we aim to reach a thousand staff in the coming decade.

Why graphene?

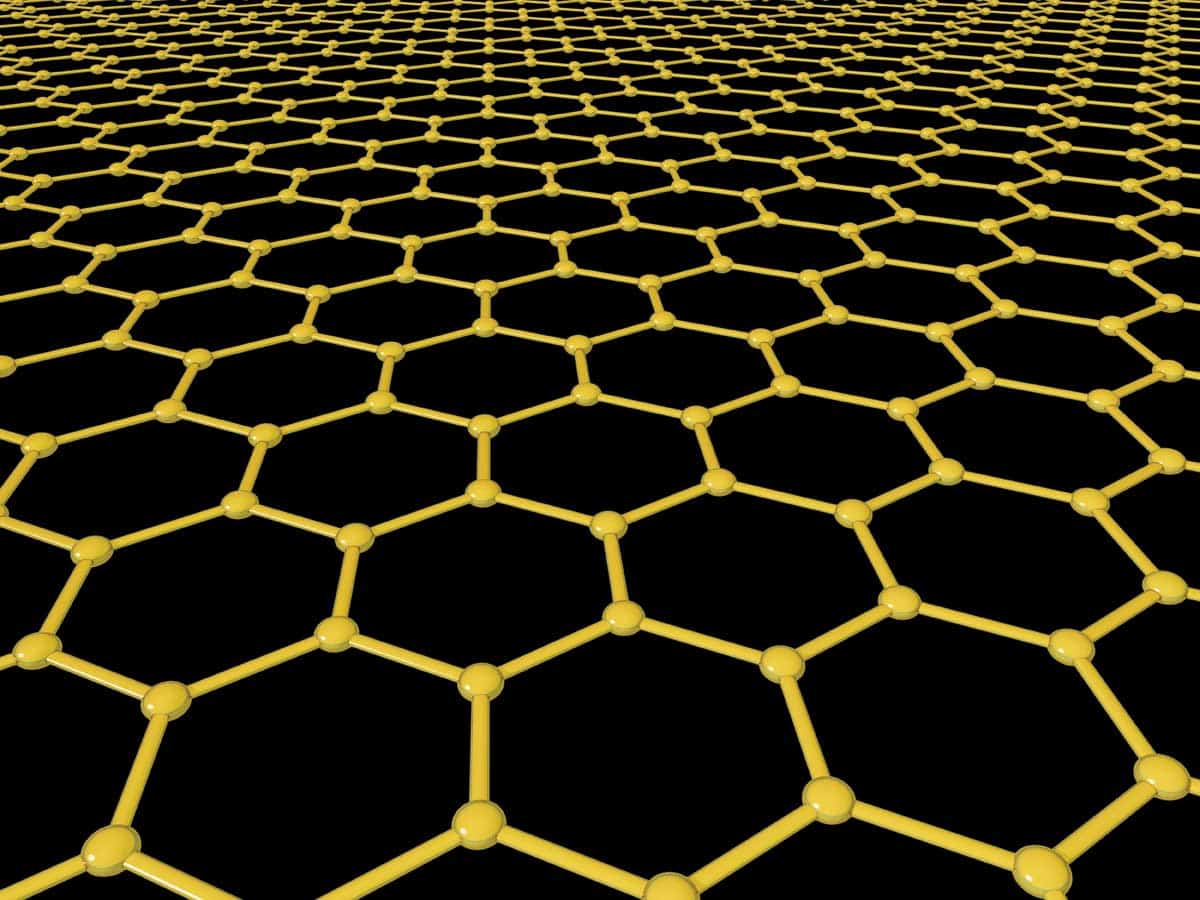

Carbon-based materials have proved promising and have derived various industrial applications such as carbon fibre, graphite and activated carbon. Graphene, being another revolutionary carbon material, has shown promise due to its unique characteristics in terms of strength, electronic and thermal whilst being lightweight and transparent. The future for the industrialization of graphene is bright because of its extraordinary structural, physical and chemical properties.

What attracted you to graphene?

I started research in graphene in 2008. Before then I worked at Peking University on carbon nanotubes research. However, after publishing almost 600 research papers, I started to realize the limitation of fundamental research and think about doing something beyond that. Then in 2010 Andre Geim and Konstantin Novoselov shared the Nobel Prize for Physics for discovering graphene.

And how did that transform work on graphene?

Researchers around the world then began clamouring for ways to use this remarkable “supermaterial”. China also fell into “graphene fever” and began to create various graphene industrial parks and companies. Initially, the overfocus was irrational and concerning, so in 2016 I decided to set up the BGI to bring graphene research on the right path and pave the way for further industrialization. I hope BGI can follow the example of the Japanese company Toray, which leads the exploration of carbon fibre material and nurtures a worldwide carbon fibre industry.

What applications of graphene are you working on at the institute?

We are currently focusing on materials such as A3 sized super-clean graphene film, 4-inch single-crystal graphene wafers, graphene-coated glass fibres as well as 30 × 30 cm2 super graphene glass. These types of materials can be used in light-emitting diode devices, fibre-optic sensors, ultrafast lasers, high-performance heaters and more other areas. We aim to develop green and mass production techniques to make low-cost graphene materials, and to explore applications of graphene in traditional and high-tech industries.

How will these be scaled-up for applications?

We hope to build mass-production lines for the best quality materials, including manufacturing and characterization equipment as well as strong commercialization team, which can move these materials from the lab to the marketplace.

What do you think are the most exciting potential applications of graphene?

We believe the best is yet to come. Graphene has a big potential in many applications. But like carbon fibre, which was initially used in fishing pole and golf clubs before it found use in civil aviation, it takes time to explore the ultimate application of graphene. It will need joint efforts from researchers and entrepreneurs who are devoting themselves to the commercialization of materials.

What challenges – both technological and commercial – does graphene have to overcome to make it in these applications?

According to a report in 2018, most of the companies worldwide claiming to produce “graphene”, are producing less than 10% of the graphene (Adv. Mater. 30 1803784). This lack of properly characterized, high-quality material has been stalling the development of applications that depend fundamentally on graphene such as advanced coatings and composites, high-performance batteries, sensors as well as electronic and optoelectronic devices. Another challenge we are facing is to find an ultimate application for graphene and then nurturing that market.

Commercializing the ‘wonder material’

Do you work with international collaborators or companies?

The BGI has been working with many academic institutes in Europe by providing graphene and single crystal graphene wafers for LED lighting devices. No commercial collaborations have begun yet.

What would mark success for the institute over the next 5-10 years?

The BGI is aiming to be leading player in a graphene industry that is set to be worth over $100bn. We also want to be an integrated enterprise that incubates multiple subsidiaries in different areas.