A transparent, viscous coating that can be brushed or painted onto any type of surface could reduce disease transmission by capturing airborne droplets. The coating, which is based on a polymer commonly employed in cosmetics, could be applied to plexiglass barriers and face shields as well as windows, walls, ceilings or even curtains. Used in this way, it could remove virus-laden particles from the air and so slow down the spread of infectious respiratory diseases like COVID-19, according to the researchers at Northwestern University in the US who developed it.

The coronavirus responsible for the current COVID-19 pandemic is transmitted through respiratory droplets and aerosols emitted when people cough, sneeze, talk and breathe. Removing these droplets – especially in confined spaces – is therefore one way of combatting the disease.

Droplets are absorbed and then dry up

The new coating is designed such that when airborne droplets come into contact with a coated surface, they stick to it rather than bouncing off as they would normally. Team leader Jiaxing Huang says that a key challenge was to keep the coating from fogging up or becoming hazy in the process. While fogging comes from light scattering by droplets, and simply making the surface hydrophilic can prevent it, hazing is due to scattering by the residue left after droplets evaporate and is a lot harder to deal with.

“Our coating works like a sponge to absorb droplets and then distributes them in the film, so preventing the formation of large, dried particulate matter responsible for light scattering,” he explains. This property makes the coating suitable for transparent plexiglass divider screens and plastic face shields, he adds, pointing out that additives such as sanitizers and pigments could further extend its applications.

Crater-like “potholes”

To test their technology, the researchers began by studying the behaviour of a stream of aerosol droplets that they directed onto a clear hydrophobic polyethylene terephthalate (PET) microscope slide in an inverted optical microscope. The size of these droplets was about 10 microns, which is typical for respiratory aerosols. Most droplets bounced or glided off this uncoated microscope slide, and therefore became airborne again.

For their coating, the researchers chose a polymer called poly(acrylamide-co-diallyldimethylammonium chloride (PAAm-DDA) – a safe, water-soluble, transparent, film-forming polyelectrolyte often used in cosmetic products and antimicrobial coatings. PAAm-DDA is also very stable in a wide range of temperatures, from -20 °C to roughly 60 °C.

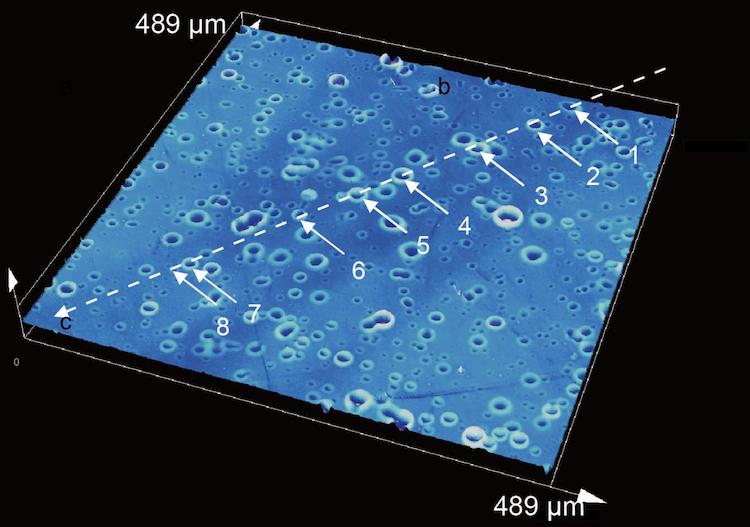

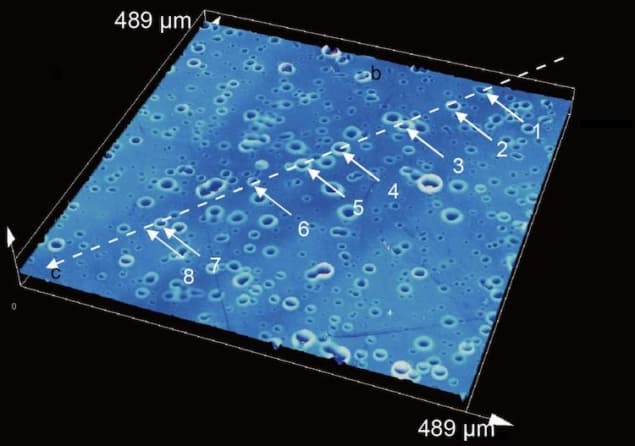

When the researchers coated their microscope slide with this polymer, the behaviour they observed was quite different: most colliding droplets were captured and subsequently absorbed by the coating. The trapped droplets partially dissolved the underlying polymer, leaving behind crater-like “potholes” once the slide had dried. Any solute or dispersant (for example, pathogens) remained in the potholes, meaning they couldn’t be released into the air again, say the researchers.

Promising result

By comparing the mass of the slides before and after the experiments, the researchers calculated that the coating captures droplets at a rate of around 105 mg/m2h. They say this is promising because the maximal droplet capture required in a room, based on the volume of respiratory droplets produced by a person speaking loudly, is estimated to be in the 10-5 to 10-2 mg/m2h range – 7 to 10 orders of magnitude below the capture capacity they demonstrated in their experiments.

The researchers also performed a qualitative experiment to evaluate whether their coating reduces the number of aerosol droplets bouncing off surfaces. In this experiment, they placed 2 x 2 cm silicon wafers coated with their polymer on the edge of a plexiglass screen to catch and visualize escaped droplets. They then directed a stream of aerosols at coated and uncoated versions of the screen from a distance of 5 cm for five minutes. Subsequent microscopy observations showed a drastic difference in the number of aerosol droplets escaping from the coated screen compared to the uncoated one.

Simulating more realistic situations

Huang and colleagues say that the main limit in this type of experiment is that people produce respiratory droplets in lower concentrations than is typical for lab-generated aerosols. Naturally-produced droplets also come in a much wider range of sizes and contain many large sub-millimetre sized droplets that splash and break up into smaller ones upon colliding with a surface.

To overcome this problem, the researchers repeated their experiments using droplets produced by an air-sprayer. This type of device has been used in previous studies to simulate different kinds of droplets and the high speed at which they are released by a person when they cough or sneeze.

They directed the droplets towards a coated and uncoated plexiglass screen for just 1 second. They repeated the experiment at least five times and found that the number of droplets escaping from the coated screen was reduced by about 80% compared to the uncoated one.

COVID-19: how physics is helping the fight against the pandemic

“The air-spray results demonstrate that the coating can reduce the escape of both fine low speed aerosols and large high-speed droplets,” the researchers say. “This should be useful for enhancing the function of transparent divider screens, which have become ubiquitous in this pandemic and are likely to continue to be used for some time yet.”

The researchers started this project during a period when the Northwestern campus was closed due to a “stay-home” order in the state of Illinois. “Luckily, however, we obtained ‘essential researcher’ status so that we could work in the lab and improvise using what we had in our labs and offices,” Huang tells Physics World. “In the future, we would really like to perform approved tests of the coating with human generated droplets and are currently in contact with potential collaborators worldwide to design such trials.”

The research is detailed in Chem.