A novel semiconducting material with high thermal conductivity can be integrated into high-power computer chips to cool them down and so improve their performance. The material, boron arsenide, is better at removing heat than the best thermal-management devices available today, according to the US-based researchers who developed it.

The size of computer chips has been shrinking over the years and has now reached the nanoscale, meaning that billions of transistors can be squeezed onto a single computer chip. This increased density of chips has enabled faster, more powerful computers, but it also generates localized hot spots on the chips. If this extra heat is not dealt with properly during operation, computer processors begin to overheat. This slows them down and makes them inefficient.

Defect-free boron arsenide

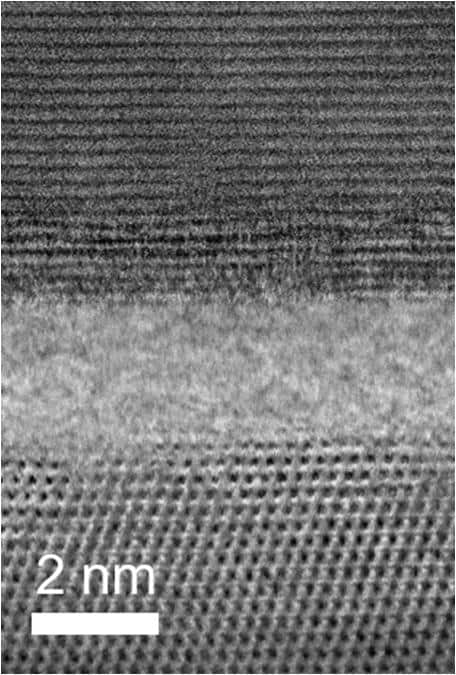

Researchers led by Yongjie Hu at the University of California, Los Angeles, recently developed a new thermal-management material that is much more efficient at drawing out and dissipating heat than other known metals or semiconducting materials such as diamond and silicon carbide. This new material is known as defect-free boron arsenide (BAs), and Hu and colleagues have now succeeded in interfacing it with computer chips containing wide-bandgap high-electron-mobility gallium nitride (GaN) transistors for the first time.

Using thermal transport measurements, the researchers found that processors interfaced with BAs and running at near maximum capacity had much lower hot-spot temperatures than other heat-management materials at the same transistor power density. During the experiment, the temperature of the BAs-containing devices increased from room temperature to roughly 360 K, compared to around 410 K and 440 K, respectively, for diamond and silicon carbide.

A new benchmark performance

“We have shown that we can process these BAs heterostructures and integrate them into a high electron mobility transistor chip design,” Hu tells Physics World. “The benchmark performance we have demonstrated shows much promise for applications in high-power electronics and future electronics packaging.”

As well as boasting a high thermal conductivity, Hu adds that BAs is ideal for managing heat for another reason too: it has a low thermal boundary resistance. This means that heat passing through it and then into an interfaced material does not slow down as much compared with other heat spreaders. “This is sort of like if the heat just needs to step over a curb when getting into an adjacent material, versus jumping a hurdle,” he explains.

Unique phonon band structure

The low thermal boundary resistance of boron arsenide stems from its unique phonon band structure. For two interfaced semiconducting materials, this resistance typically depends on the mismatch between the vibrational spectra of phonons (vibrations of the crystal lattices) of both. This mismatch is usually calculated by comparing the temperature at which phonons oscillate with the highest frequencies in each. A small difference in this so-called Debye temperature should result in a lower thermal boundary resistance. Conversely, a big difference implies a higher thermal boundary resistance.

Heat transport theory goes universal

Most semiconductors (including silicon, germanium, gallium arsenide and gallium nitride) and metals have Debye temperatures below 700 K, the researchers explain. Prototype high thermal conductivity materials such as diamond and cubic boron nitride (BN), on the other hand, have much higher Debye temperatures (over 2000 K) because of their large phonon velocities. The thermal boundary resistance for diamond and BN interfaces (once integrated with typical semiconductors) should therefore be high, which somewhat limits their potential applications in thermal management despite their high thermal conductivities. For example, the interface between diamond and GaN has aDebye temperature mismatch of over 1500 K, resulting in a thermal boundary resistance of ~30 m2 K GW−1. BAs, in contrast, has a much lower Debye temperature value (of ~700 K), so it should have a lower thermal boundary resistance after integration.

Spurred on by their findings, Hu and colleagues now plan to integrate the material they have developed into various device architectures and radio-frequency (RF) circuits. Indeed, they have already succeeded in self-assembling the material to develop high-performance flexible thermal interfaces for wearable electronics and soft robotics.

The researchers report their work in Nature Electronics.