Some physicists take the quality of their coffee very seriously while others will settle for any old bean as long it keeps them alert during an overnight experimental run. Now, they could use multispectral imaging and artificial intelligence to select their beans, thanks to research done in Brazil.

According to the Specialty Coffee Association of America, a specialty coffee must achieve a score of 80 or more out of a possible 100 on the association’s quality scale. Coffee is usually tested at three stages – raw beans, roasted beans and tasting coffee made from the beans. This is done by sending raw beans to three independent people (called cuppers) who do the tests.

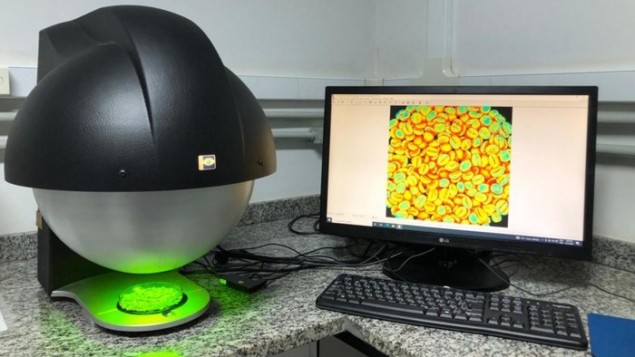

This is an expensive and time consuming process, so Winston Pinheiro Claro Gomes at the University of São Paulo and colleagues have developed a much more hi-tech way of sorting coffee beans. The team developed its system by first doing multispectral imaging measurements on 16 different samples of green coffee beans. This technique illuminates a sample with light at several different wavelengths and then measures the light reflected by the sample – and also fluorescence from the sample.

Looking for differences

Ten of the samples were award winning specialty beans, and six were standard beans bought at a local market. Artificial-intelligence systems were then used to look for differences and similarities between the multispectral images of the higher and lower quality samples.

The analysis revealed that the better beans tended to be more uniform in shape when viewed with visible light, whereas poorer beans tended to have more intense fluorescence signals. The team believes that these signals are related to the myriad chemical compounds (including caffeine) that are found in coffee. Variations in the levels of some of these compounds can be used to distinguish between different types of bean, so the team is hopeful that its technique could soon be used to identify beans with the potential to be specialty coffees.

The research is described in Computers and Electronics in Agriculture.

As the Brazilian research shows, nature provides use with a bounty of useful chemicals and materials. One such material is chitin, which occurs in the exoskeletons of animals such as insects and crustaceans. Chitin has found a number of industrial and medical uses and could even be used as a building material on Mars.

Environmentally friendly

Now, Liangbing Hu at the University of Maryland and colleagues have used a chitin-derived material called chitosan to create a battery electrolyte. An electrolyte is the material in a battery through which ions flow as the battery is charged and discharged. It is often made from toxic or flammable chemicals, so researchers are trying to develop new materials that are more environmentally friendly.

A key feature of the team’s new electrolyte is that it can be biodegraded by microbes in about five months. What is more, the chitosan can be derived from crab shells and other seafood waste – and even from some types of fungi – making it a sustainable product.

Hu and colleagues used the electrolyte to create a battery that is based on zinc rather than lithium, the latter being a much rarer metal. Hu says that well-designed zinc batteries are cheaper and safer than their lithium counterparts. Indeed, their zinc and chitosan battery has an energy efficiency of 99.7% after 1000 battery cycles – which the team says makes it a viable option for storing energy generated by wind and solar systems.

The battery is described in Matter.