Researchers have succeeded in making rechargeable pouch-type lithium batteries with a record-breaking energy density of over 700 Wh/kg. The new design comprises a high-capacity lithium-rich manganese-based cathode and a thin lithium metal anode with high specific energy. If developed further, the device could find use in applications such as electric aviation, which requires much higher energy density batteries than those available today.

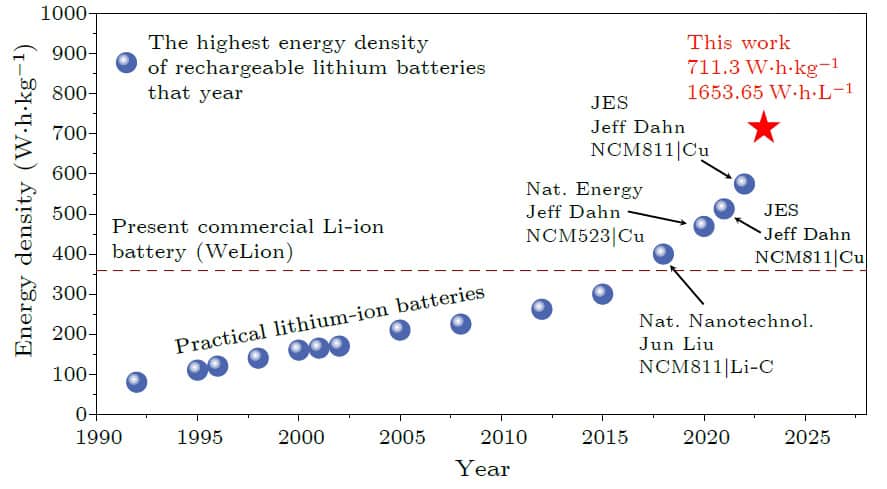

Lithium-ion batteries are a key technology for helping to reach climate neutrality goals. They are increasingly being used to power electric vehicles and as the principal components of domestic devices that store energy generated from renewable sources. The technology has greatly advanced too: since first commercialized by Sony in 1991, the energy density of lithium-ion batteries has increased from 80 Wh/kg to around 300 Wh/kg.

Achieving a truly carbon-free economy, however, will require better-performing batteries than current lithium-ion technology can deliver. In electric vehicles, for example, a key consideration is for batteries to be as small and lightweight as possible. Achieving that goal calls for energy densities that are higher than 400 Wh/kg. The problem is that today’s lithium-ion batteries mainly contain intercalation-type cathodes (for example, LiFePO4, LiCoO2 or LiNixMnyCozO2, x+y+z=1) and graphite-based anodes, and the energy density of these electrodes is approaching its upper limit.

High charge-discharge voltage

In the new work, the researchers led by Xiqian Yu and Hong Li of the Institute of Physics, Chinese Academy of Sciences in Beijing, have manufactured practical pouch-type rechargeable lithium batteries by using an ultrathick high-discharge capacity Li1.2Ni0.13Co0.13Mn0.54O2 cathode with an areal capacity exceeding 10 mAh/cm2 and a lithium metal anode. The high charge-discharge voltage of the lithium-rich manganese-based oxides allows for a higher lithium-ion storage capacity.

“The anode electrode employs ultrathin metal lithium incorporated using a separator coating technique, which addresses the annoying issue of reversible deposition of ultrathin lithium of large surface capacity,” explains first author Quan Li.

The devices boast a gravimetric energy density of 711.3 Wh/kg and a volumetric energy density of 1653.65 Wh/L, both of which are the highest in rechargeable lithium batteries based on an intercalation-type cathode, Li tells Physics World.

“With respect to the battery manufacture, our extremity battery structure design (including the use of ultrathin current collectors) was tailored to minimize the usage of auxiliary materials while enhancing the proportion of active materials in the entire battery,” he adds. “This synergistic approach is what enabled the ultrahigh energy density of the batteries.”

Long-range electric vehicles and electric aviation could benefit

The new devices could benefit long-range electric vehicles and electric aviation, both of which place increasingly high demands on battery energy density. The research could also help address some of the inherent issues associated with battery technology, says Li.

“For instance, it offers insights into how to balance safety and other important factors in high-energy density batteries, which will help in the practical realization of high-energy density batteries in the future. Research on batteries with energy densities approaching theoretical limits will also help improve our knowledge of solid-state ionics and solid-state electrochemistry, allowing perhaps for technological innovation in new materials and battery systems.”

Lithium-ion batteries recharge in the cold

The researchers, who report their work in Chinese Physics Letters, explain that a trade-off always exists between the energy density, cycle performance, rate capability and safety of lithium-ion batteries. Safety is a primary requirement, but elevated energy density will increase the risks during battery operation, they say. “Energy density must be gradually improved while ensuring safety,” says Li. “Our goal is to enhance battery safety performance through solid-state battery technology, making high-energy density batteries more practical.”

The cycle performance of high-energy density batteries also still lags behind that of currently commercialized batteries, he adds. “This parameter needs to be comprehensively considered to meet the requirements of specific fields. It will therefore take considerable time for ultrahigh-energy density batteries to be practically applied. Addressing the challenges that hinder their practical usage will be the ongoing direction of our future research endeavours.”