A new method for creating and controlling exchange bias in an antiferromagnetic single-layer film has been developed by researchers in the US and Switzerland. The method involves low-energy ion implantation into the film, and it has the potential to advance the development of antiferromagnetic spintronics devices.

Exchange bias refers to a shift in the position of the hysteresis loop of a ferromagnet along the horizontal axis (applied magnetic field). This can occur when an antiferromagnet layer and a ferromagnet layer are brought close together, pinning the magnetization of a ferromagnetic layer. Exchange bias materials play important roles in spintronic technologies such as the read head sensors in hard disk drives; spin valves; and the magnetic tunnel junctions used in digital memories.

Generating a strong exchange bias field between a ferromagnet and an antiferromagnet requires a good quality interface between the two materials. However, achieving this in thin films can be challenging. Moreover, to obtain exchange bias, the system must be heated above the antiferromagnet’s Neel temperature and then cooled in the presence of a magnetic field. This thermal treatment can cause diffusion between the two layers, which reduces significantly the exchange bias. To prevent this, diffusion barriers are generally incorporated into the stack structure. However, this increases the complexity and thickness of the device, making it unsuitable for the miniaturization of spintronic devices.

Material for the future

Now, Cory Cress and Steven Bennett at the US Naval Research Laboratory, and researchers there and at the Paul Scherrer Institute and Oak Ridge National Laboratory have used low energy ion implantation to create an appreciable exchange bias in the antiferromagnetic material iron–rhodium (FeRh). And, they have done this without the need for a ferromagnetic layer.

Ion implantation is a common technique in materials science and engineering and is used to modify the properties of a material by introducing ions into its surface or bulk. The process involves creating a beam of ions that is then directed at a target material.

In their experiments, the team first deposited a single-crystal FeRh film onto a magnesium oxide substrate (see figure below). The sample was then heated to 730 °C and cooled in a process called annealing. This put the FeRh film into a face-centered cubic-type crystal structure. This phase exhibits a high-speed meta-magnetic transition from an antiferromagnetic to a ferromagnetic state when the temperature exceeds about 400 K. Additionally, the FeRh film possesses a switchable magnetic moment that can quickly flip direction, making it promising for various spintronic applications.

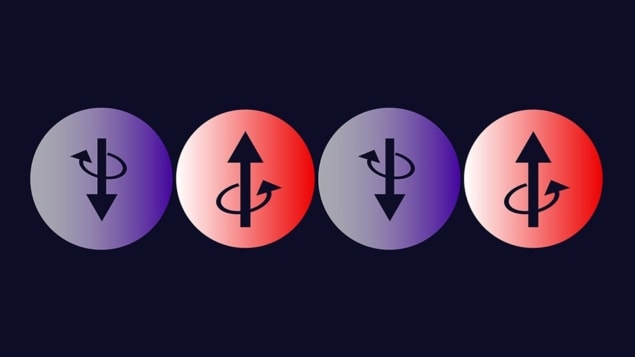

Taking a cue from their previous study of tuning a meta-magnetic transition temperature in FeRh through ion implantation, the team implanted low-energy helium or iron ions into FeRh films at room temperature. This created ferromagnetic surface layers that were adjacent to the antiferromagnet layer. This created a relatively large exchange bias effect of 41 Oe for the iron-implanted film and 36 Oe for the helium implanted film.

According to the researchers, these findings are promising because the exchange bias effects previously observed in FeRh have been typically very low or only seen below room temperature. As a result, the team believes creating exchange bias by implantation in FeRh could lead to the development of advanced antiferromagnetic devices.

The origin of exchange bias has remained a long-standing puzzle since its discovery, despite the development of various models that try to explain it. In this study, Cress, Bennett and colleagues aimed to shed further light on the origin of this phenomenon by subjecting ion implanted FeRh films to one hour of annealing either at 400 °C or 700 °C. After the annealing process, the team noted a substantial decrease in the exchange bias field of both implanted films. This was attributed to the healing of defects formed during implantation and restoration of the film’s antiferromagnetic state near the surface.

Defects are responsible

By using annealing to regain the pristine properties of the helium implanted film, the researchers found compelling evidence that any exchange bias present in the film is due to the defects caused by the ion implantation and not because of any changes in the FeRh composition due to the addition of iron ions. Furthermore, the team used a domain state model to explain these results, proposing that non-magnetic defects within the antiferromagnetic layer play crucial role in forming and stabilizing the exchange bias field.

To gain further insight into the exchange bias of FeRh films, the team employed polarized neutron reflectometry. This technique measures magnetization as a function of depth by directing polarized neutrons on to the surface of the film and measuring the intensity of the reflected neutrons.

Using this technique, the researchers observed the pinned uncompensated magnetic moments within the antiferromagnetic region of the film. They found that these uncompensated moments result from defects, such as vacancies created by ion implantation. When coupled with an adjacent ferromagnetic layer, the vacancies result in the exchange bias phenomenon. According to the researchers, these findings provide a convincing proof for the domain state model of exchange bias.

The team’s findings are reported in the Journal of Materials Chemistry C could potentially lead to the application of the domain state model in diverse magnetic spin systems.