A new and highly accurate electrospray technique could be used to create coatings of biomaterials and bioactive compounds for medical applications such as vaccinations. The technique, which was developed by researchers at Rutgers University in the US, is better at targeting the region being sprayed than existing methods and provides increased control over the electrical discharge of the charged particles being deposited. The result is that more of the spray ends up coating the area of interest.

Electrospray deposition involves applying a high voltage to a flowing liquid to convert it into a mist of fine particles with charged surfaces. As these charged particles travel towards the target area, they evaporate and deposit a solid precipitate.

While the technique is efficient at coating massive objects such as car bodies, it is much less so for smaller targets. This is because charge builds up around the target and effectively screens it from the “view” of the spray. Without a target, the spray destabilizes into a bigger, less directed mist, explains Jonathan Singer, a materials engineer at Rutgers and the leader of a study on the new technique.

Droplets “see” the target

In the study, which is detailed in Nature Communications, Singer and colleagues kept the droplets directed at the target by placing a large, grounded support underneath it that is isolated from the spray droplets by insulating coatings. “The purpose of this support is to stabilize the electric field and make sure that any droplets that approach the target ‘see’ it,” Singer explains.

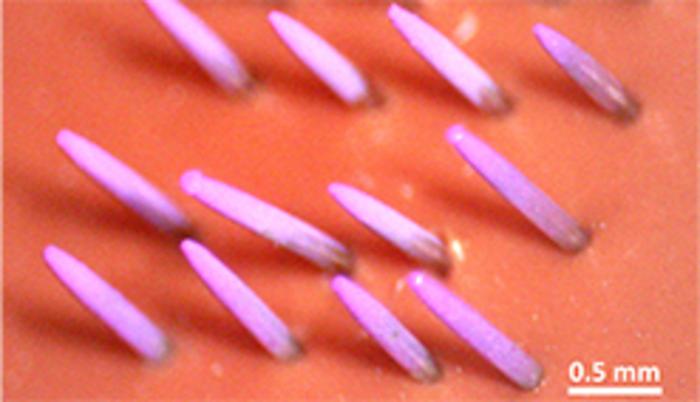

The team demonstrated this technique with several materials, including biocompatible polymers, proteins and bioactive molecules, and on both flat and microneedle array targets, which are complex surfaces. These bioactives can be costly, but their clinical usefulness means they are increasingly being employed to coat medical devices such as stents, defibrillators and pacemakers that are implanted in the body. More recently, they have also appeared in products such as patches that deliver drugs and vaccines through the skin. In either case, being able to deposit them more efficiently means wasting less of the precious material.

“Current methods only achieve about 40% efficiency,” Singer notes, “but by incorporating different strategies to manipulate the ‘charge landscape’ of the particles being deposited, we can produce coatings that contain almost 100% of the sprayed material on a surface measuring 3 mm2.”

High efficiencies in a wide range of materials

As well as being more efficient, the new technique is more flexible than existing methods, which often require a lot of optimization of the material’s formulation to get the right viscosity and surface tension for a specific film. “One of the things we showed in our work is that we can achieve high efficiencies for coating a wide range of materials, including small molecule drugs, vaccines and polymers,” Singer says. “This means that we can use a wider range of formulations and focus that formulation development on whatever that function is.”

In the case of vaccines, for example, this might mean focusing on formulations that are better at getting the drug into target cells, he tells Physics World.

Until now, the team’s research has focused on dry coating microneedle arrays with DNA vaccines, in collaboration with their sponsor GeneOne Life Science Inc., which manufactures small-molecule drugs and vaccines. “Microneedle arrays are easier to administer and less painful than typical injections, and dry-coated drugs are generally more stable,” explains Singer. “This means they could be transported to remote or underserved populations. The fact that the coatings can be deposited on complex surfaces should also allow for other applications, such as more permanent implants like vascular stents that are treated with drugs to prevent clotting.”

Microneedle patch combines cold plasma and immunotherapy to treat melanoma

Further down the line, being able to target patterned electrode arrays will also enable applications in microelectronics in so-called “lab-on-chip” diagnostics, he adds.

The next steps for this technology are to demonstrate its effectiveness in animal experiments and ultimately in humans. “We are also continuing research into translating the hardware we need to transfer the process from the lab bench to a more commercial product,” says Singer, adding that university-industry collaboration has been crucial for speeding their past work into clinical trials.