Researchers in the Netherlands and the US have shown for the first time that qubits – the building blocks of quantum computers – can be mass-produced using standard processes developed for manufacturing conventional integrated circuits. The breakthrough paves the way for developing powerful quantum machines that require thousands or even millions of identical qubits for full-scale operation.

Quantum computers promise a revolution. A large-scale quantum device could, for example, simulate chemical reactions involving thousands of molecules, thereby accelerating the development of medicines and new materials. To get there, however, quantum computers will eventually need millions of qubits, whereas today’s early-stage versions contain only a modest number – all of which must be manufactured in the laboratory.

Producing qubits on the same scale as the computer chips found in smartphones and other modern digital devices has proved elusive for several reasons. The processes that produce these conventional chips have undergone a decades-long trajectory of development and standardization. To benefit from these advances, large-scale qubit production must follow the same design and fabrication rules.

In principle, this should be possible for so-called spin qubits, which are made from the same silicon material as integrated circuits and work by controlling the spin of charge carriers (electrons and holes) in semiconductors. Spin qubits are, however, difficult to make and need to operate at temperatures below 4K to achieve long coherence times.

Going large

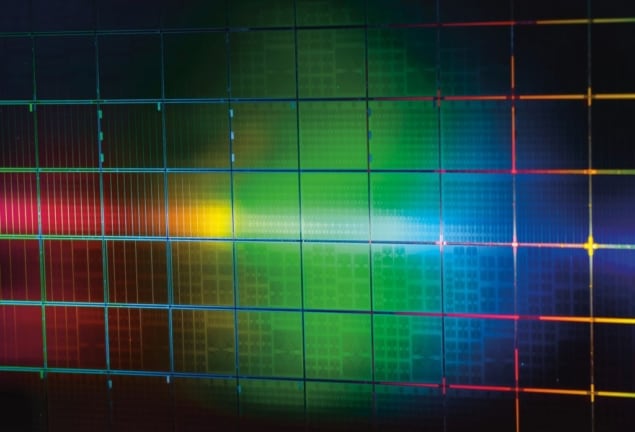

In the latest work, researchers at QuTech (a collaboration of TNO and Delft University of Technology) in the Netherlands, together with colleagues from Intel in the US, designed and manufactured silicon spin qubits using Intel’s state-of-the-art optical lithography 300mm wafer process line. Previous work to produce qubits on wafers had instead used electron beams to pattern the structures on the wafer, which is much slower. The optical lithography process, in contrast, uses equipment similar to that used for commercial integrated circuits, and made it possible to fit more than 10 000 qubit arrays on a single 300 mm wafer.

The researchers tested two properties of their processed wafer: device yield and sample uniformity. The former is measured by checking how many of the manufactured devices operate properly, with current flowing and contacts not leaking. The latter is measured by comparing the room-temperature threshold voltage of individual qubit gates. The results indicated a yield and sample uniformity of 98%, with consistent uniformity throughout the wafer and only a few devices at the edge not functioning. When the team repeated the tests at temperatures of 5K and lower, the results correlated well with those obtained at room temperature.

Advanced qubit fabrication

Lieven Vandersypen, a researcher at QuTech and a co-author of a Nature Electronics paper describing the work, says that this is the first time anyone has produced complete qubits using the same processes employed to mass-produce integrated circuits. He adds that the number of qubits produced is several orders higher than could be accomplished with laboratory equipment. More importantly, the yield is higher, as lab production has a failure rate “on a good day” of at least 50%. Vandersypen notes that the high yield is remarkable because the design rules of standard processes lack the flexibility that university cleanroom equipment provides, meaning that the process could reduce qubit quality if not properly designed.

Manufacturing silicon qubits at scale

Silvano de Franceschi, a researcher at CEA in Grenoble, France who was not involved in this work, says it is important that one of the leading manufacturers of microprocessors is now using its advanced fabrication facilities to make qubits. He is also impressed by the researchers’ efforts to correlate statistical device properties at low temperature with those measured in ambient conditions, noting that this is “important for optimization of the fabrication processes”. However, de Franceschi adds that electron beam patterning is more flexible for initial optimization and could have a similar yield if integrated in an industry-standard way. Furthermore, in his view the level of charge disorder in this first generation of qubits does not seem low enough to allow for large-scale qubit integration. “We are just at the beginning and there is certainly margin for improvement,” he says.

Vandersypen says that he and his colleagues now plan to increase qubit production still further. “We also want to improve the control over the qubits and test new concepts to increase the scalability,” he tells Physics World. In his view, the high reliability and volume of the new production process will enhance the rate of progress across the field.