A magnetic system that dynamically adjusts the surface properties of a material used for solar-driven water purification has been created by researchers in China. Developed by Liangti Qu at Beijing’s Tsinghua University and colleagues, the system achieved higher evaporation rates when compared to static surfaces.

Clean water is in short supply in many parts of the world and purification and desalination processes can be energy intensive. As a result, developing ways of using solar energy to purify water by evaporation has been the subject of extensive research, yet it is far from being in widespread use. Even though this approach utilizes mainly the energy from the Sun to separate water from contaminants, it is still too slow for many practical applications.

Interfacial solar vapour generation offers a way to increase the efficiency of evaporation by concentrating the energy of the Sun’s rays only at the surface of water. Still, with static systems there is little control on the flow of water and its vaporization, and the harsh chemical environment of untreated water leaves such systems prone to rapid deterioration.

Now, Qu and colleagues have created a dynamic magnetically responsive system with controlled porosity and a shifting surface that achieves much higher evaporation rates than static counterparts.

Transport spikes

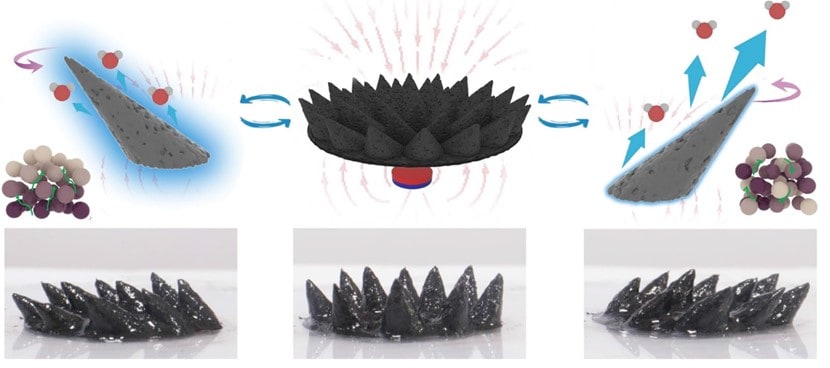

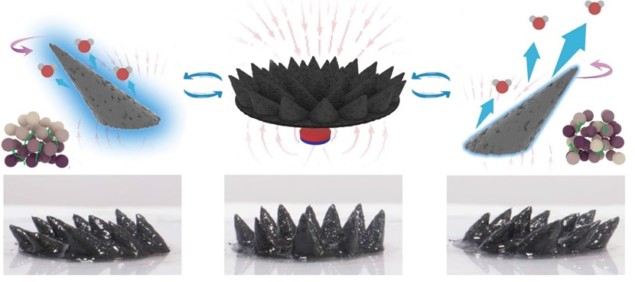

At first glance, the glistening spiky fluid in the above figure does not look like a water-purification system. Created by the team, it is a slurry of graphene-wrapped iron oxide nanoparticles that are mixed with the water to be purified. The special graphene coating prevents the nanoparticles from aggregating together, allowing them to dynamically reconfigure under an external magnetic field, or to disassemble simply by washing the slurry with a stream of water. Crucially, the material accelerates the diffusion of water from the bulk to the surface of the system by two orders of magnitude compared to the uncoated nanoparticles.

Solar-powered water purifier is inspired by pufferfish

When the slurry is exposed to an external magnetic field, arrays of cones are formed, in a manner characteristic of ferrofluids. The high surface-area cones move, deform and spin along with the motion or change of the applied magnetic field. Thanks to the spiky surface and the concentration gradient it creates, any salt precipitation that is left behind when the pure water evaporates only occurs at the tips. This allows the sunlight to get through unblocked to the water in the slurry, unlike flat systems where salt precipitation covers the surface entirely. But the spikes are not the only structures of interest. On a smaller scale, a network of pores with diameters between hundreds of nanometres and tens of millimetres allows the rapid transport of water as well as fast disassembly of the structure when needed.

Spinning structures

Generally, porous structures are known to have enhanced performance when it comes to water transport. However, other purification systems that use porous materials rely on the passive flow of liquid water and vapour. As a result, slow water diffusion causes the accumulation of water vapour at interfaces, limiting the evaporation rate.

This problem can be solved by agitating the air around the system, which disrupts the water vapour and speeds up the evaporation process. In the team’s design, this agitation is done by the ferrofluid as the conical arrays rotate in response to a dynamic external magnetic field. This macroscopic motion is also accompanied by the reconfiguration of the magnetic nanoparticles on the microscopic scale to a disordered state while maintaining the conical shape on a macroscopic level – as shown in the figure above. This rearrangement aids salt, heat, and water vapour circulation in the system, enhancing the diffusion of vapour. As a result, the rotating systems show a 23% increase in the evaporation rate compared to the static systems when the rotation speed is above 100 rpm.

Hierarchy of cones

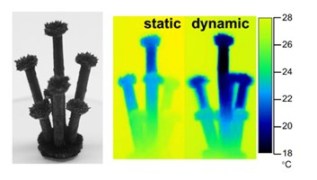

Movement is not the only way to increase the performance of the magnetic systems. The team also created more complex hierarchal 3D structures, that break the record for the static evaporation rate and exceeded the theoretical limit for evaporation when used dynamically. These proof-of-concept structures were constructed through the synergetic design of the magnetic forces between macroscopic magnets and the magnetic nanoparticles.

The image above shows the well-distributed conical arrays supported on stalks that extend the space for the vapour diffusion process. Since areas with higher evaporation rates lose energy to the atmosphere faster, surface temperature was used to monitor the evaporation rate. Real-time infrared thermal imaging revealed cooler temperature distributions for the dynamic structures compared to static structures.

While the systems are still in their preliminary phase of research, they offer exciting insights into the innovative future possibilities in water management and purification.

The research is described in Nature Communications.