The James Webb Space Telescope (JWST) is scheduled to launch on 24 December. To mark the event, Physics World is publishing a series of blog posts on the telescope’s technological innovations and scientific missions. This post is the second in the series. Read the first here.

Building a mirror the size of the James Webb Space Telescope’s (JWST) 6.5-metre primary isn’t a problem per se. Building a 6.5-metre mirror that can fit inside an Ariane 5 rocket fairing just 4.57 metres wide, without being too heavy to launch into space – well, that is a problem, and the task of solving it fell to NASA’s Lee Feinberg, who leads the telescope’s optical team.

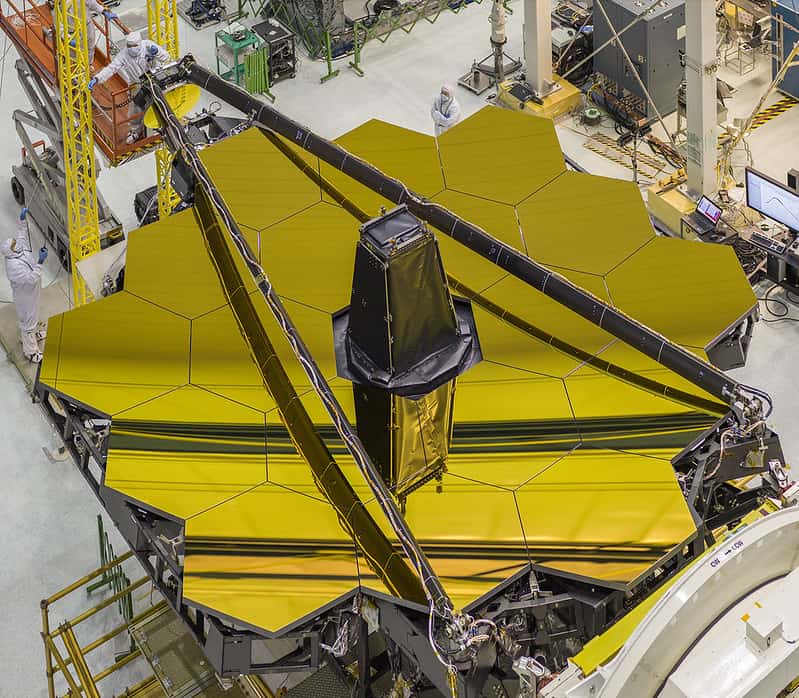

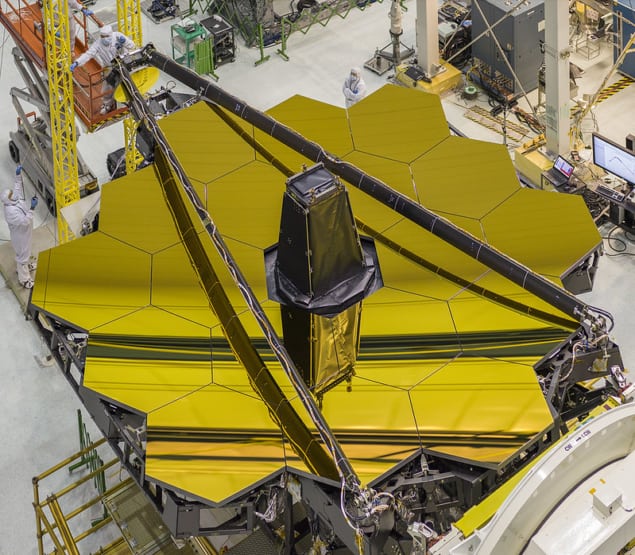

“The primary mirror has a very elegant design,” Feinberg tells Physics World. The essence of that design, he explains, is that the primary mirror is foldable: the final version comprises 18 hexagonal segments, with three of the segments on either side forming “wings” that fold down.

The JWST also has a secondary mirror 0.74 metres across, plus a smaller tertiary mirror to remove the scope’s astigmatism and flatten the focal plane ready for its scientific instruments. Together, these three mirrors make up an arrangement known as an off-axis three-mirror anastigmat that corrects for spherical, coma and astigmatism errors while providing the instrument with a larger field of view. But these capabilities contribute launch headaches of their own. “The real trick is that the booms holding the secondary mirror are eight metres long, so you also have to fit that inside the rocket,” Feinberg notes. “And then there’s the sunshield. So we had to fold up for all those reasons.”

All three mirrors are made from a new type of gold-plated, optical-grade beryllium that remains stable at the telescope’s operating temperature of 36 K. This material, known as O-30, was created specially for the JWST by the materials firm Materion, and its advantages include a low mass and good technical performance at cryogenic temperatures. The material’s stiffness, for example, means that when the mirror is plunged into the freezing cold behind the telescope’s sunshield, it does not distort too much. Given all these factors, and the size of beryllium billets that were considered reasonable to work with, making a hexagonal segmented system that could fold up was “the best option”, Feinberg says.

A similar hexagonal system has operated on the twin 10-metre Keck telescopes in Hawaii since the 1990s, and Feinberg acknowledges that his team learned a lot from Keck’s optical design. As at Keck, all 18 segments of the JWST’s primary mirror, as well as its secondary, have robotic actuators to nudge them into focus.

However, while Keck has sophisticated wavefront sensors to align its segments, the JWST optical team decided that such a system would be too complex to operate autonomously in deep space. Instead, the telescope will use its science camera. “The first test image that we’ll get will actually be 18 separate stars, because of the 18 separate segments each acting like a telescope,” Feinberg explains. The telescope will then use its camera and a specially developed algorithm called Phase Retrieval to measure the shape of the wavefront and adjust the shape of the primary mirror until all 18 segments focus as one.

The ten-billion-dollar gamble: What the JWST will do (and why it’s taken so long)

The design of the telescope’s mirrors is typical of the technology and techniques that had to be pioneered to make the JWST workable. “Across the board, we felt that for everything we did, there was no playbook,” Feinberg says. “We were really changing the way we were doing things.”

A case in point: while the 2.4-metre mirror on the Hubble Space Telescope is contained within what is effectively a giant telescope tube assembly, the JWST’s mirrors are open to space. As the next post explains, protecting these mirrors from the heat and glare of the Sun is a tough challenge.

Next: How the JWST shields itself from the Sun