A new material that is twice as magnetostrictive as others in its class could be a significant boon for computer-chip developers. The material’s unusual ability to expand and contract in response to tiny pulses of electric current has attracted interest from the chip manufacturer Intel, which is investigating possible replacements for the CMOS (complementary metal-oxide-semiconductor) technology that has dominated the industry for decades.

In today’s CMOS-based transistors, the semiconductor’s resistance changes when a voltage is applied across an insulating gate. This switching mechanism has long been the mainstay of electronics, remaining dominant even as transistors have shrunk down to mere nanometres in size. Reductions in the gate voltage and frequency, however, have not kept pace with reductions in chip size, and further decreases in operating voltages are unlikely because of the so-called Boltzmann limit of current control. Researchers are thus looking for alternative technologies.

Shape changes flip the magnetic field

One line of investigation concerns magnetostriction, or the tendency of an iron-containing material to expand and contract slightly as pulses of electric current are applied to it. Magnetostriction is associated with ferromagnetism and is perhaps best known as the source of the familiar hum that emanates from fluorescent lights and transformers. However, because changes in the shape of a magnetostrictive material also cause the material’s magnetic field to flip, this sometimes-irritating phenomenon could prove key to next-generation “magnetoelectric” devices.

Devices of this type would use such electrically-induced magnetic fields to store the digital one and zeros of binary data. Unlike conventional CMOS technology, these switching devices wouldn’t require a steady supply of electricity, so they should require much less energy to operate.

Unwanted order

Most magnetostrictive materials contain rare-earth elements, which are becoming too scarce and expensive to be used in the quantities required for chip manufacture. In the new work, researchers led by John Heron of the University of Michigan focused instead on an iron-gallium alloy with the chemical formula Fe1–xGax. Heron explains that the magnetostriction of this alloy normally increases with increasing concentrations of gallium. However, these increases eventually level off at around x = 19% before decreasing sharply as the higher amounts of gallium start to form an ordered intermetallic atomic structure.

To overcome this problem, the researchers used a process called low-temperature molecular-beam epitaxy to “freeze” the atoms in the compound, so preventing them from forming this unwanted order. This technique enabled the researchers to boost the fraction of gallium in the material to x = 30%, increasing its magnetostriction by tenfold compared to unmodified alloys.

“Spray painting”

Heron likens the technique, which is detailed in Nature Communications, to “spray painting” with individual atoms. The technique has a further advantage in that it allows the material’s magnetostrictive properties to be measured simply by applying it to a surface that deforms slightly when a voltage is applied.

Multiferroics and topological materials for the post-CMOS world

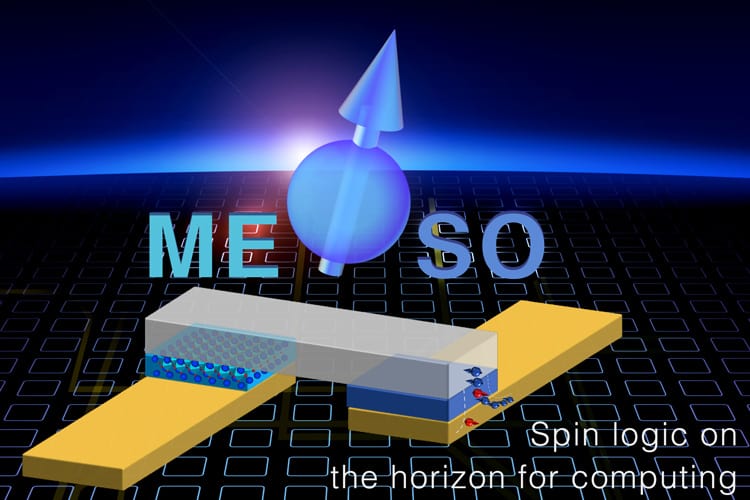

The magnetoelectric devices in this study are several microns across, and the researchers acknowledge that this is large by today’s computing standards. However, they hope that their collaboration with Intel will help them shrink their devices down to a size that is compatible with the company’s magnetoelectric spin-orbit (MESO) device programme.

“Intel is great at scaling things and at the nuts and bolts of making a technology actually work at the super-small scale of a computer chip,” Heron says. “They’re very invested in this project and we’re meeting with them regularly to get feedback and ideas on how to ramp up this technology to make it useful in the computer chips that they call MESO.”

Heron and his colleagues have filed for patent protection on their technology through the University of Michigan’s Office of Technology Transfer.