Glasses have long fascinated materials scientists because they are classed as extremely high-viscosity liquids, yet their macroscopic material properties mostly resemble solids. Now researchers in the US and China have studied how metallic glasses flow by measuring their shear stresses to strain rates over nine orders of magnitude. They found a universal scaling law, which applies to other glasses, foods, soils and even ant colonies.

Glasses are difficult to model because they appear to comprise flowing molecules that have suddenly lost the energy to flow and are locked into a disordered, non-equilibrium state. Scientists refer to this as a glass transition. However, unlike a change of state from liquid to solid – which is easily defined as the formation of an ordered atomic lattice – a glass transition is nebulous and very difficult to define in terms of changes in the ways a material can deform in response to stress.

It has been observed that the stained-glass windows in old churches are often thicker at the bottom than at the top. This has led to the controversial idea that this glass has been flowing downward very slowly over centuries. However, glasses tested on laboratory timescales do not do this, but instead behave like brittle solids that usually break before they bend.

Atoms, not molecules

Now, the materials scientist Mingwei Chen of Johns Hopkins University in the US and colleagues at Shanghai Jiao Tong University in China have investigated further by studying metallic glasses: “If you deal with silica glass or organic glass or polymer glass, you’re talking about molecules,” explains Chen; “and for molecules the vibrations and the dynamics are much more complicated. We started from metallic glass because you can just deal with single atoms.”

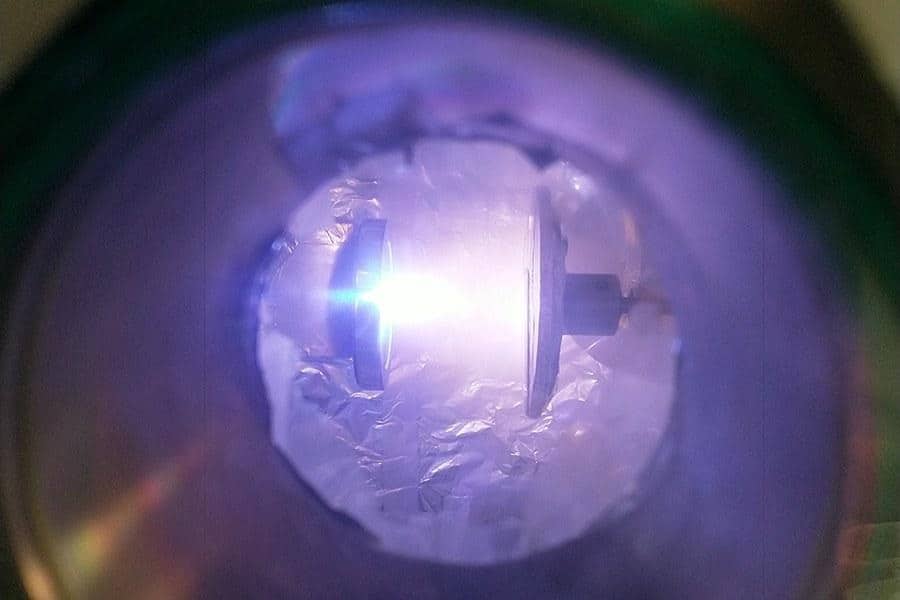

To produce low strains, they clamped a metallic glass cantilever at one end and pressed a diamond tip called a nano-indenter into the other. By measuring the rate at which the resulting stress decreased over time, they could infer the capacity of the atoms in the glass to flow in response to the applied stress. For higher stress measurements, this kind of technique would simply have broken the cantilever or flattened it completely. Instead the researchers pushed the tip of the nano-indenter into the centre of a wedge of glass, pressing it in a known distance and monitoring the change in stress over time.

To confirm that the two techniques gave the same results, they measured the stress response to intermediate strain rates using both techniques, finding perfect agreement. This allowed them to join their two graphs together, mapping out the relationship between stress and strain rates over nine orders of magnitude.

Liquid to solid

Their results suggest that, at low strain rates, the glass behaves as a Newtonian fluid, with stress proportional to applied strain. At intermediate strain rates, the material behaves as a non-Newtonian, viscous-elastic fluid. Finally, at high strain rates, the atoms become almost unable to relax any further because they lack the energy to rearrange quickly enough. The system therefore behaves like a solid.

The researchers compared these results with measurements made on a wide variety of other substances ranging from polybutadiene rubber to mayonnaise, soil, and aggregations of fire ants. They believe that all these “glasses” appear to follow a universal scaling law in which the transition from liquid-like to solid-like behaviour is regulated by a constant relationship between temperature, density, stress and strain rate.

Earthquake zones

The work has already found applications: “Two years ago, we used exactly this equation to produce a super-high melting temperature metallic glass – it can be used at over 1000 ˚C,” says Chen. Beyond this, understanding and potentially controlling the conditions that lead to soil liquefaction under stress could be very useful in earthquake zones.

Alumina glass bends rather than breaking

Donald Stone, a materials scientist at the University of Wisconsin-Madison, describes the research as “kinda cool”. He adds, “You might expect that if you look at the properties of a glass…then something governs the stress scale and something governs the strain rate scale, so if you can normalize the two things for all different materials you get a universal behaviour. In retrospect it wouldn’t surprise me, but I think it’s fairly profound.”

However, he adds: “I’ve done experiments on metallic glasses whose properties can be changed by annealing [heating followed by slow cooling]. It’s not clear how this [research] applies because I could change the stress scale [without changing] the strain rate scale.”

The research is described in Nature Materials.